Our reasoning and expectations behind this.

we wanted wheel carer mounts that held the wheel with the cavity facing outwards so have fabricated our own as they don’t seem to be available.

Work on the modified wheel carrier mounts.

Sheet metal and studding cut to size.

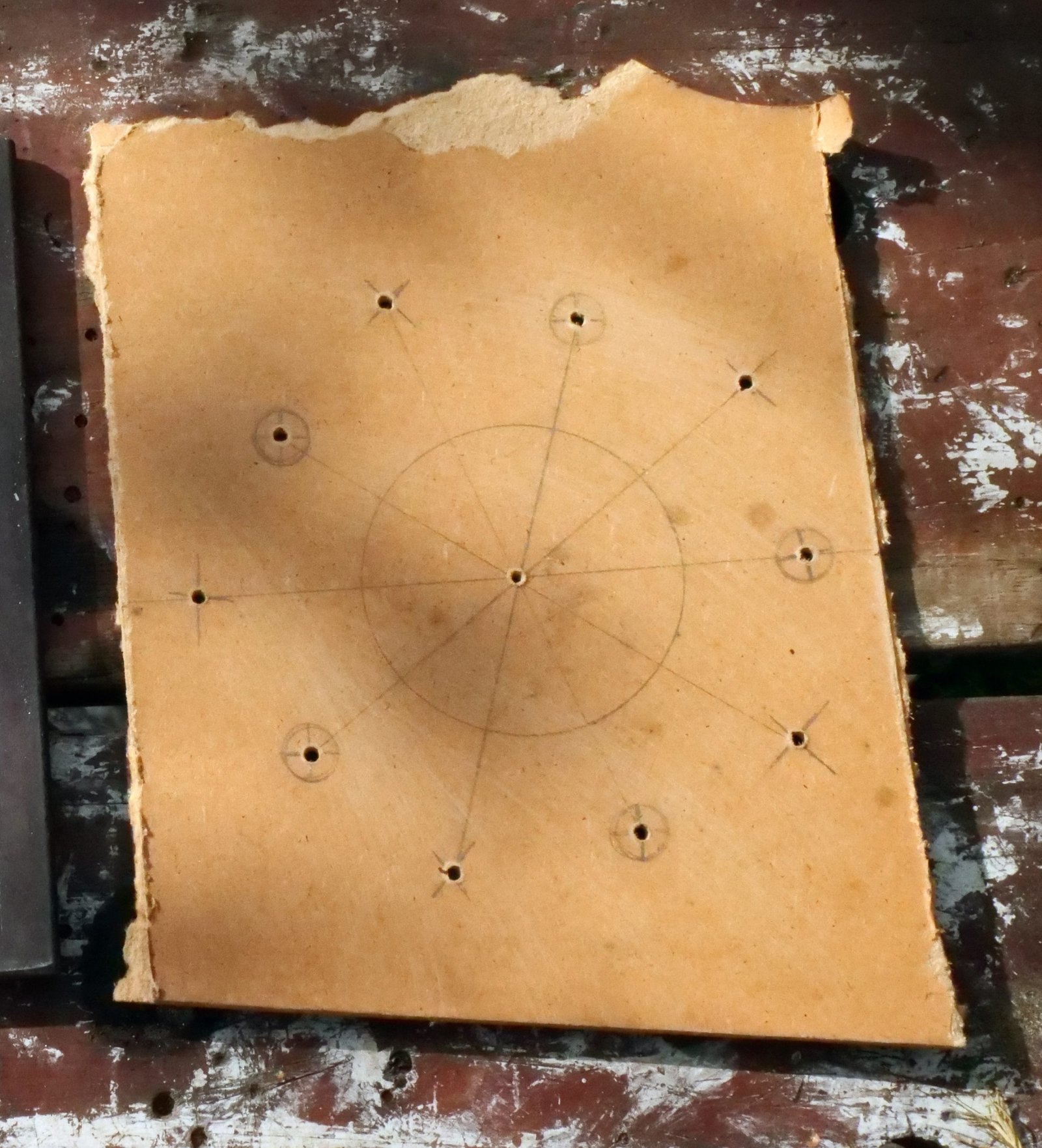

Hole pattern template marked out & drilled.

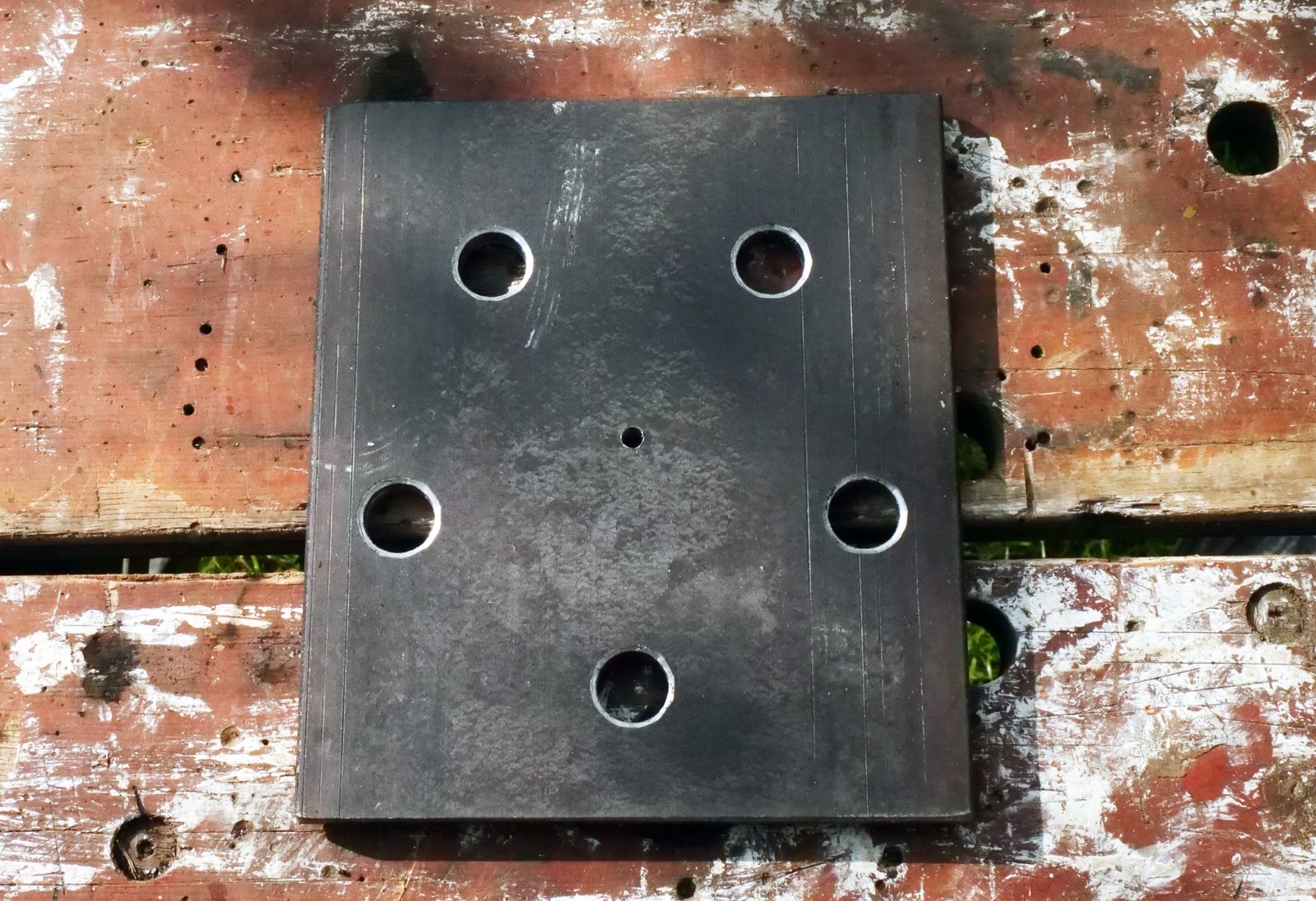

Holes were drilled in the first plate and HT studs were prepared.

Studs temporarily fitted in the wheel.

Base plate test fitted (successful).

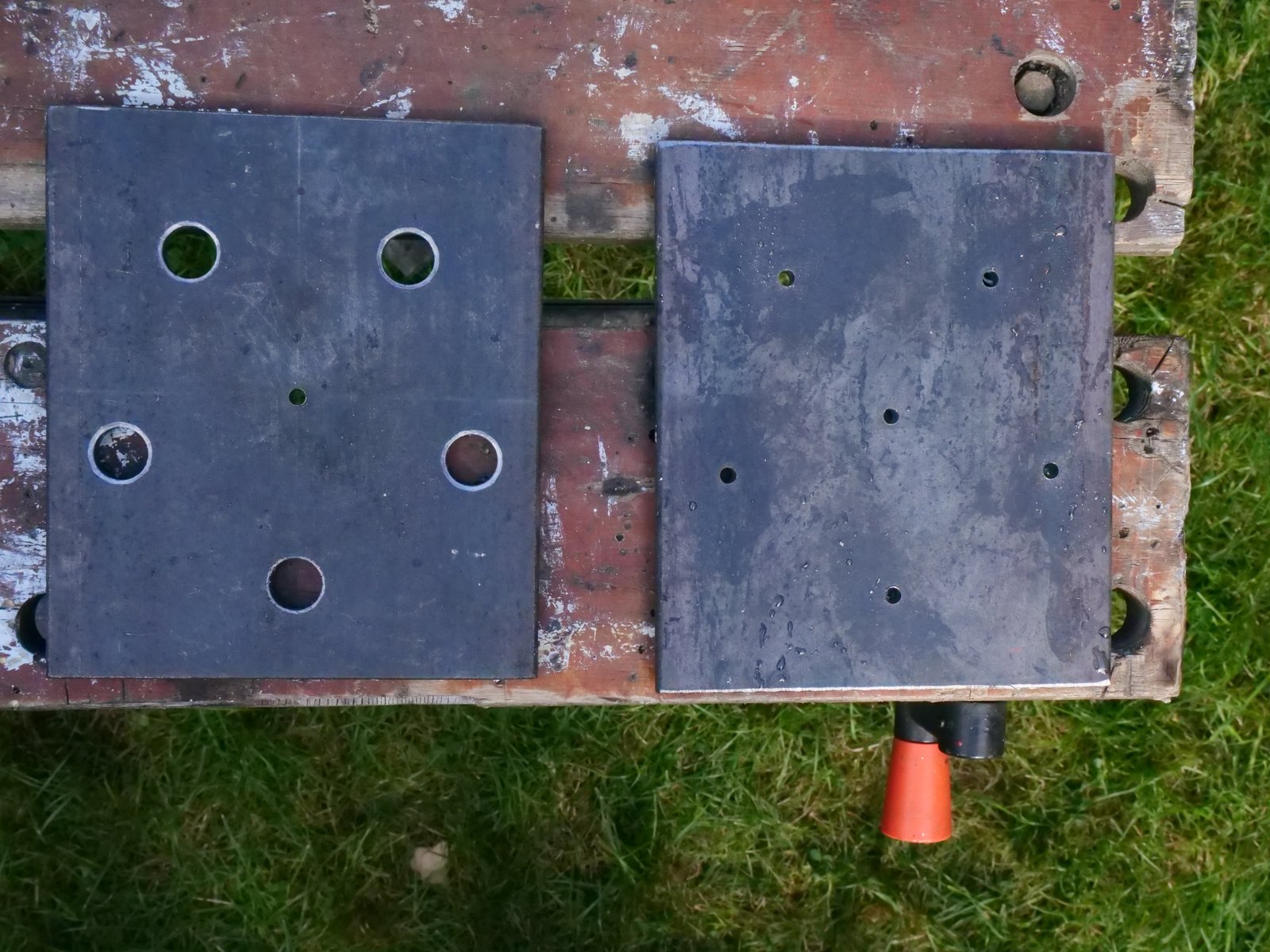

The second base plate was marked up and drilled.

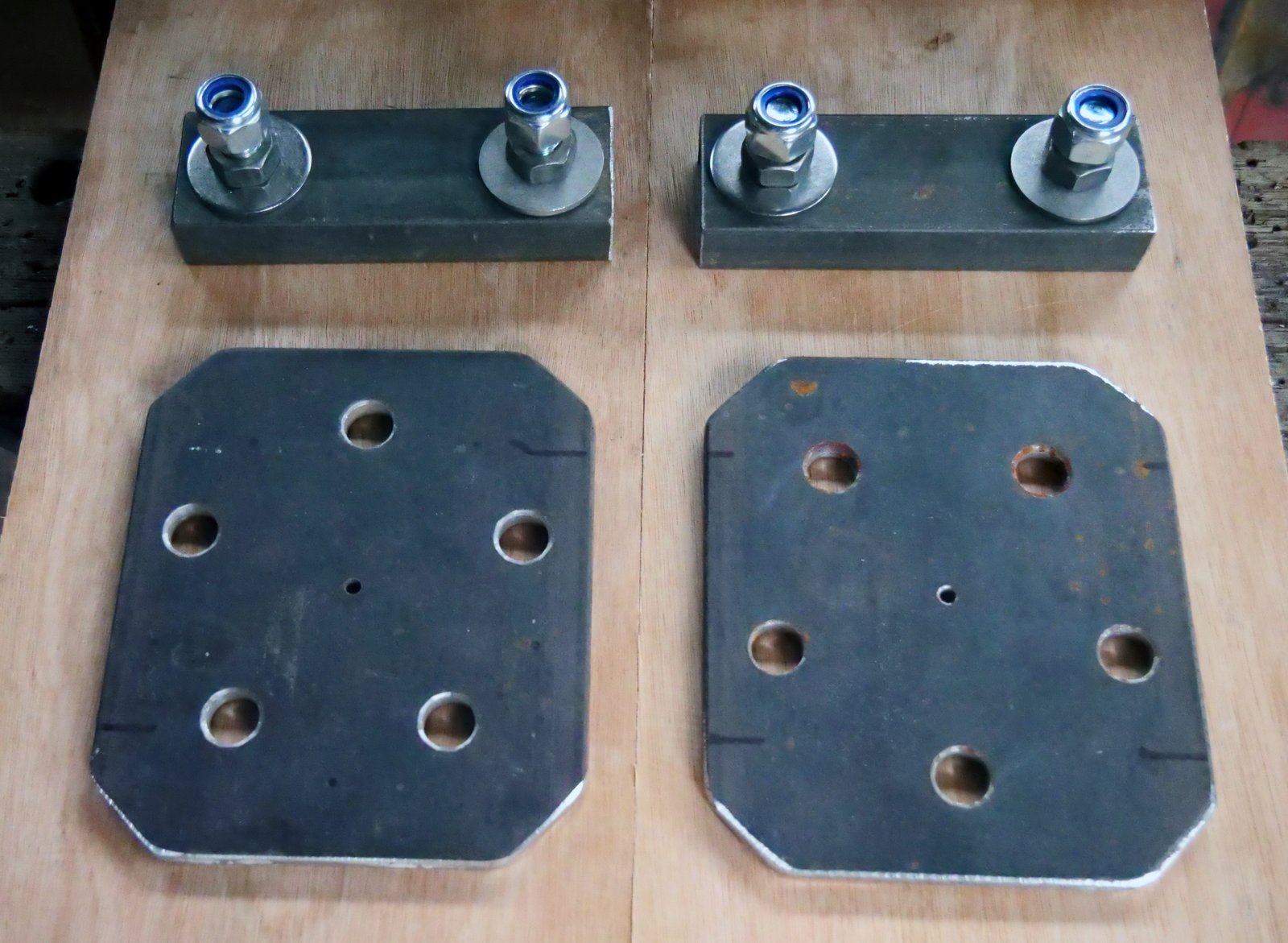

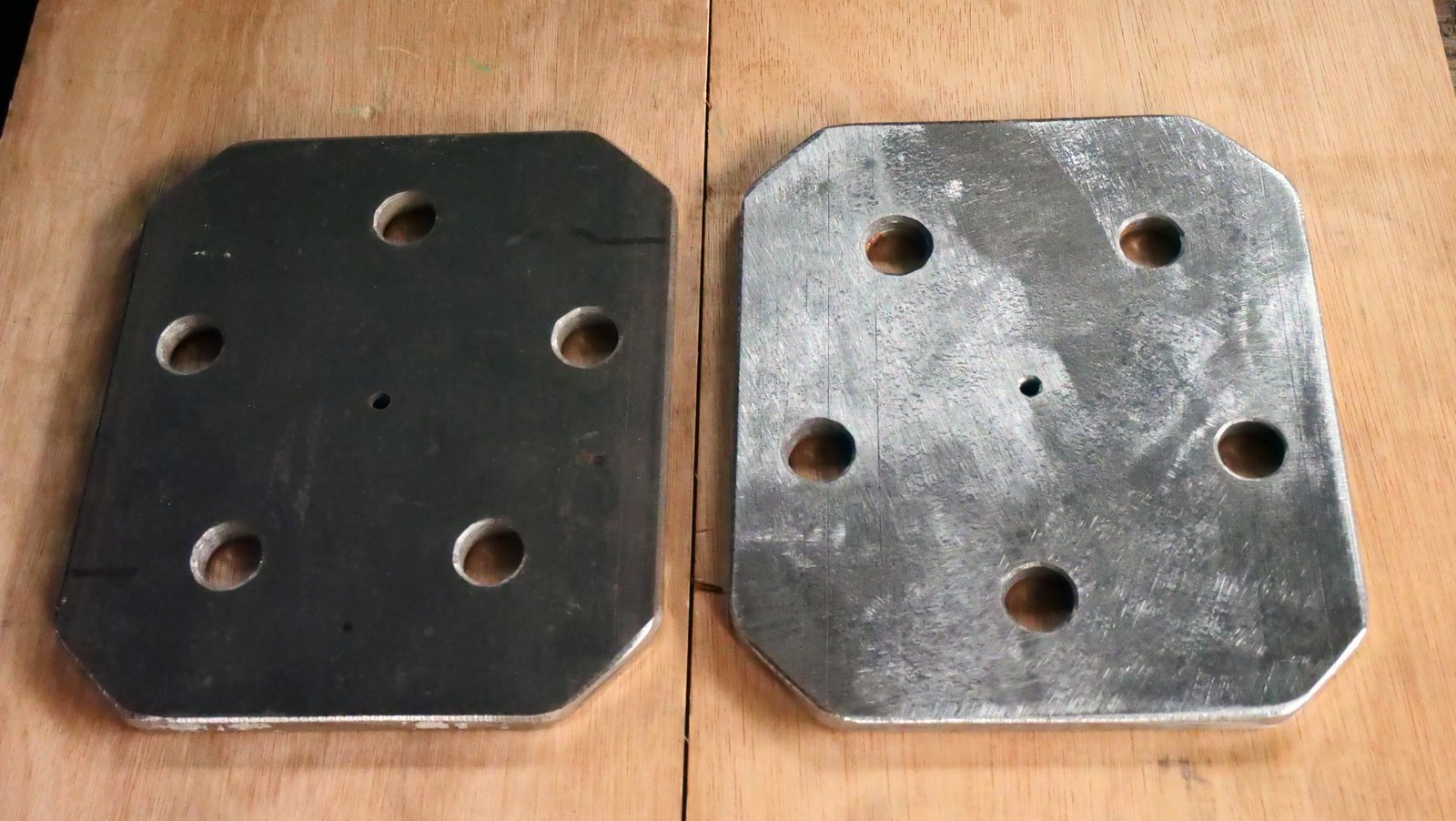

Base plate corners & sharp edges removed.

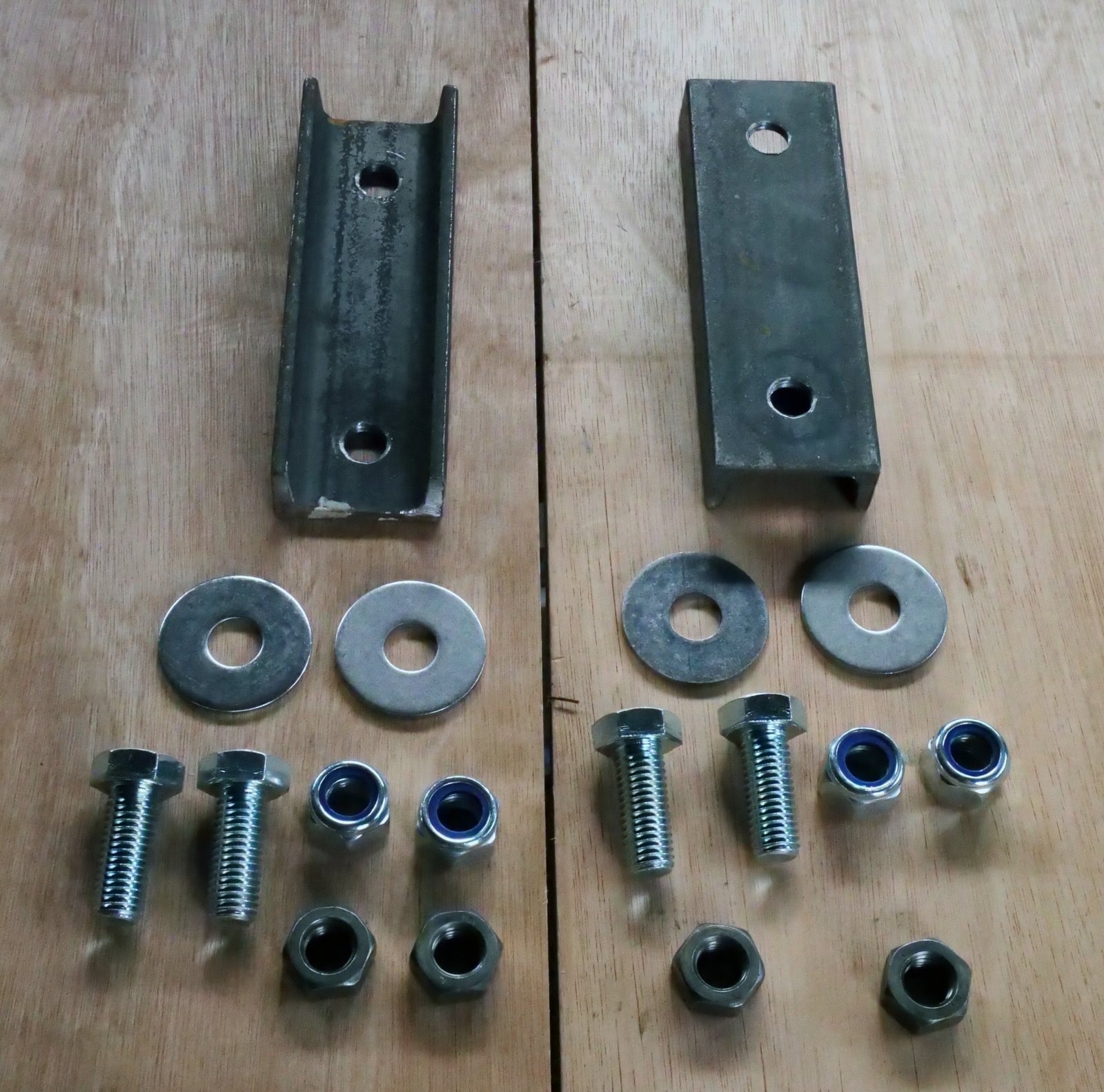

Spacers for both wheel mounts are cut, drilled & ready for the bolts to be welded in place, prior to being welded to the base plates later after the studs are fitted.

(Plane nuts used for fabrication to be replaced with the locknuts when finally fitted).

Base plates cleaned up and ready for welding.

Galvanizing removed from the ends of the HT studs ready to be welded,

(these are structural welds so need a bit more care in their preparation).

First wheel carrier base plate, clamped up and almost ready to weld.

More info and Photos and a full write-up to follow soon.

In-use reviews.

Our conclusions.

Pros.

Cons.

Other related or affected items.

See Attachments for the swing-out arms.

…