The work on the front bash-plate.

Bash plate bolted in its original position on the sub-frame, and hinges tacked welded in position, rod put through all 3 hinges to ensure they align.

Hole drilled in center hinge plate to align with the drain hole in sub-frame.

Bolts removed and hinge articulation checked

Hinges were welded in place and a coat of red oxide was applied.

Sub-frame sent off to be galvanized.

Modification to allow for the upgraded winching points marked and cut.

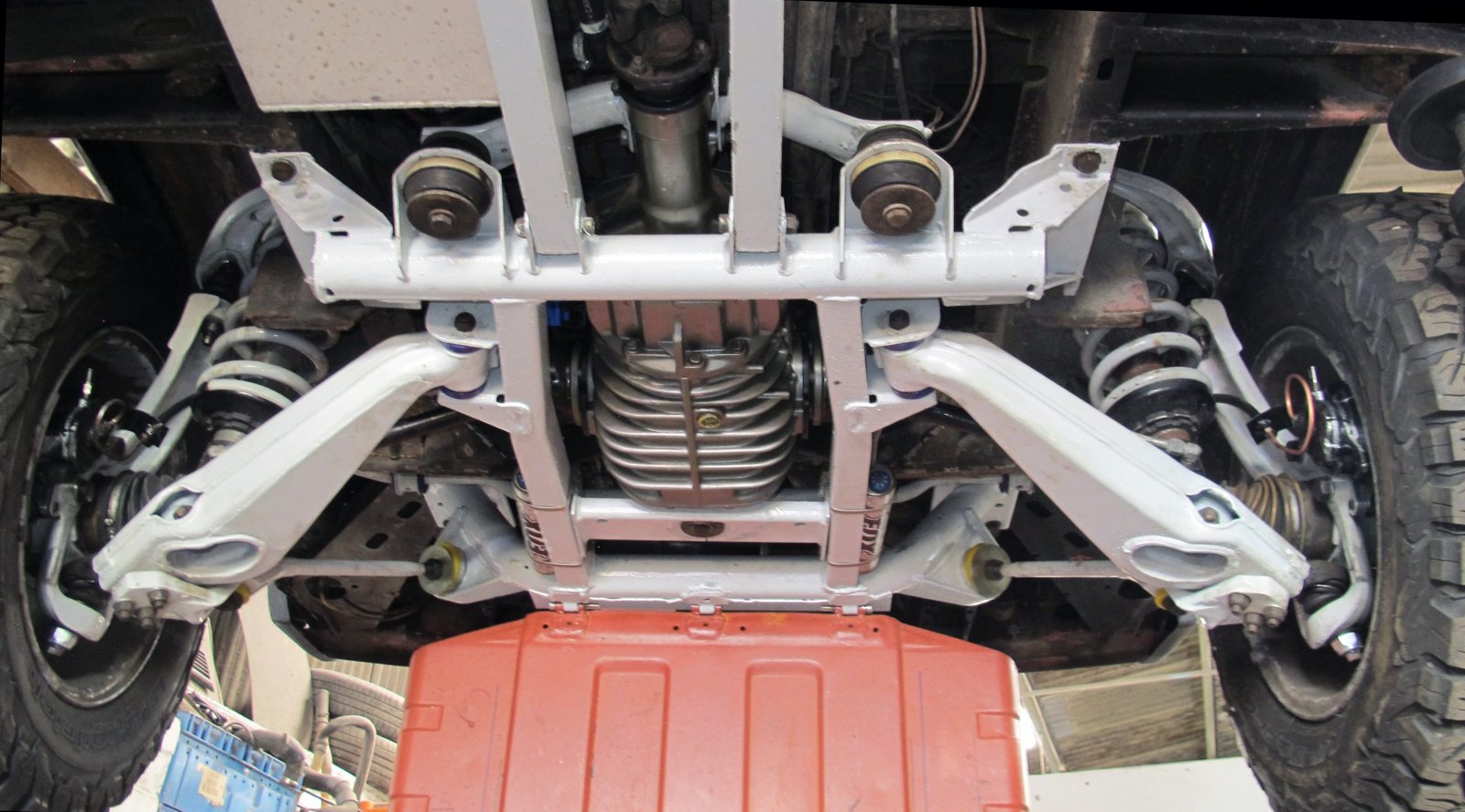

New winch points fitted, plus sub-frame and other galvanized and painted parts back on the van, all the bushes were also replaced with poly bushes at this point.

Cut parts on bash plate, tack welded in position, and a test fit on the van to check the clearance.

The Hinges work well but we need to make sure this doesn’t (can’t) happen while driving.

(We will probably fit chains at the front).

Infill plate’s tack-welded in the gaps, then along with the other parts all welded in place.

Any sharp edges are rounded and cleaned up.

Welded on both sides, as access was available.

The old hole for the original tow loop has now been filled, plus work continues on the quick-release front securing points and the fabrication of an internal load restraints system (Photos soon).

Original weight = ?

Finished weight = ?

More info and photos and a full write-up to follow soon.

Home build – Pros.

You get what you want (or close to it).

Home build – Cons.

Only myself to blame if it all goes wrong.

Takes longer than expected, (always).